As the sun rises over the tobacco fields, a centuries-old technique is set in motion, with invisible hands meticulously crafting the flavors and aromas that will soon fill our pipes and cigars.

Flue curing tobacco, an art passed down through generations of skilled cultivators, holds the key to unlocking a world of unparalleled taste and aroma. But what exactly is flue curing? And why does it play such a crucial role in creating tobacco with superior flavor?

In this deep dive, we will voyage into the heart of flue curing tobacco, unraveling its ancient origins and exploring the intricate steps involved in its process.

Flue Curing Tobacco: The Key to Richness and Complexity in Every Puff

The Origins of Flue Curing: A Time-Honored Tradition

Flue curing tobacco is a traditional method that has been used for centuries to enhance the flavor and aroma of tobacco leaves. This time-honored technique involves a meticulous process that requires skill and expertise. Let’s delve into the origins of flue curing and discover the secrets behind its superior results.

The practice of flue curing can be traced back to the United States in the early 17th century. It was initially developed as a means to preserve tobacco leaves during transportation. Tobacco farmers quickly realized that flue curing not only preserved the leaves but also imparted a unique flavor and aroma that set it apart from other curing methods.

Flue curing involves the controlled exposure of tobacco leaves to heat. The process begins by hanging the harvested tobacco leaves in large barns or curing chambers. These chambers are specifically designed to facilitate the flow of heated air. The heat is generated by burning hardwoods such as oak or hickory.

As the heat rises, it passes through a flue, which is a system of ducts that distribute the hot air evenly throughout the curing chamber. This gentle and regulated heat causes the tobacco leaves to undergo a chemical transformation, resulting in the development of rich flavors and enticing aromas.

One of the main advantages of flue curing tobacco is that it allows for the removal of moisture at a controlled pace. The gradual elimination of moisture ensures that the tobacco leaves retain their essential oils, which contribute to the distinctive taste and aroma. This method also reduces the risk of mold and rot, ensuring the quality of the cured tobacco.

Flue curing tobacco requires expertise and attention to detail. Farmers need to monitor the temperature, humidity, and airflow within the curing chambers to achieve optimal results. The duration of the curing process can vary depending on several factors, including the type of tobacco and desired flavor profile.

Over time, flue curing has become not only a preservation technique but also an art form. Skilled tobacco farmers have honed their craft, fine-tuning the process to produce tobacco with unparalleled flavor and aroma. The use of flue-cured tobacco in premium blends and cigars has become a testament to its outstanding qualities.

Understanding the Science Behind Flue Curing

Flue curing tobacco is a process that has been used for centuries to enhance the flavor and aroma of tobacco leaves. This method involves hanging the leaves in specially designed barns and subjecting them to controlled heat and airflow. But what exactly happens during flue curing? Let’s dive into the science behind this fascinating process.

During flue curing, the tobacco leaves go through a series of chemical reactions that contribute to the development of their unique characteristics. The primary goal of this process is to remove moisture from the leaves while preserving their flavor and aroma. This is achieved by carefully controlling the temperature and humidity levels in the curing barns.

The first step in flue curing is withering, where the freshly harvested tobacco leaves are hung in the barns. The heat and airflow are gradually increased to accelerate the drying process. As the leaves lose moisture, enzymes naturally present in the tobacco are activated.

The next crucial stage is the actual flue curing, which involves raising the temperature in the barns to around 120-160°F (49-71°C). This increase in temperature triggers a complex series of chemical reactions, including the breakdown of chlorophyll, the conversion of starches into sugars, and the release of volatile compounds.

The breakdown of chlorophyll is particularly important as it helps to reduce the grassy and green flavors typically associated with raw tobacco leaves. This process also leads to the transformation of the leaves’ color from green to various shades of brown. Additionally, the conversion of starches into sugars contributes to the sweet and caramel-like flavors often found in flue-cured tobacco.

The release of volatile compounds during flue curing is another critical factor in developing the desired flavor and aroma. These compounds, such as esters and aldehydes, contribute to the characteristic fruity, floral, and nutty notes that make flue-cured tobacco so sought after.

After the flue curing process is complete, the tobacco leaves are allowed to cool gradually, reducing the risk of damage. They are then sorted and processed further to remove any remaining impurities. The result is tobacco with a distinctively mellow and sweet flavor, making it highly desirable for use in cigarettes, cigars, and pipe tobacco.

Flue curing is a delicate and time-consuming process that requires careful monitoring and expertise. The precise control of temperature, humidity, and airflow is essential to achieve the desired flavor and aroma profiles. While modern technology has made the process more efficient, flue curing remains an art that is passed down through generations of tobacco farmers.

A Look at the Flue Curing Process

Flue curing tobacco is a process that has been used for centuries to enhance the flavor and aroma of tobacco leaves. It is a technique that involves carefully drying tobacco leaves using hot air in a controlled environment. The result is a rich, flavorful tobacco that is highly sought after by smokers and manufacturers alike.

The flue curing process begins with the harvesting of tobacco leaves. Once the leaves are harvested, they are carefully arranged in a curing barn. These barns are specially designed to allow for the circulation of hot air while maintaining a consistent temperature and humidity level. This is crucial for the tobacco leaves to undergo the curing process successfully.

Once the leaves are in the curing barn, the flue curing process can begin. The first step involves heating the barn using burners or heaters. The heat is directed through a system of pipes, known as flues, which run through the barn. As the hot air circulates through the flues, it gently dries the tobacco leaves.

The temperature and humidity in the curing barn are closely monitored throughout the process. The heat is gradually increased, and the humidity is carefully controlled to ensure that the tobacco leaves cure evenly and develop the desired flavor and aroma. This delicate balance is crucial in achieving the superior quality tobacco that flue curing is known for.

The flue curing process typically takes several weeks to complete. During this time, the tobacco leaves gradually change color, from a vibrant green to a rich golden brown. This change in color is a sign that the leaves are undergoing the desired chemical changes that result in the enhanced flavor and aroma.

Once the tobacco leaves have completed the flue curing process, they are removed from the barn and carefully graded. Leaves that have been properly cured will have a uniform color and texture, indicating that the process was successful. These leaves are then used to create various tobacco products, from cigarettes to cigars and pipe tobacco.

Flue cured tobacco is highly valued in the tobacco industry due to its superior flavor and aroma. The process of flue curing allows for the development of complex, well-rounded flavors that are highly sought after by smokers. The resulting tobacco is often described as smooth, mellow, and full-bodied.

Unveiling the Flue Cured Tobacco: Flavor and Aroma Profile

During the flue curing process, the tobacco leaves are hung in specially designed barns. These barns are equipped with flues, which are channels that allow hot air to circulate around the leaves. The heat is carefully regulated to ensure that the leaves are subjected to the optimal temperature and humidity levels.

One of the key benefits of flue curing tobacco is the removal of excess moisture from the leaves. This helps in preventing the growth of mold or mildew, which can negatively impact the flavor and aroma of the tobacco. By reducing the moisture content, flue curing also facilitates the preservation of the leaves, allowing them to be stored for longer periods without compromising their quality.

Flue curing tobacco also contributes to the development of desirable flavors and aromas. The controlled heat causes chemical reactions within the tobacco leaves, resulting in the formation of complex compounds that are responsible for the characteristic taste and smell of flue-cured tobacco. These compounds include sugars, which caramelize during the curing process, adding a hint of sweetness to the tobacco.

Furthermore, flue curing helps to reduce the harshness and bitterness that may be present in the raw tobacco leaves. Through the controlled application of heat, the curing process breaks down certain molecules, resulting in a smoother and more mellow flavor profile. This makes flue-cured tobacco a popular choice for those who prefer a more refined taste.

The duration of the flue curing process can vary depending on the desired flavor and aroma profile. Generally, the longer the leaves are exposed to heat, the more pronounced the flavors and aromas become. However, it is a delicate balance, as excessive curing can lead to an overpowering taste or the loss of delicate nuances.

Conclusion: Flue Curing as the Key to Superior Flavor and Aroma

Flue curing tobacco is not just a common practice in the tobacco industry, but it is also the key to achieving superior flavor and aroma in tobacco leaves. This age-old technique has been used for centuries to enhance the overall quality of tobacco, making it highly sought after by tobacco enthusiasts and connoisseurs.

Flue curing tobacco is an essential step in the production of high-quality tobacco with superior flavor and aroma. By carefully drying the leaves in a controlled environment, the process enhances the taste, reduces harshness, and improves the overall smoking experience.

Whether you’re a tobacco enthusiast or simply curious about the intricacies of tobacco production, understanding the significance of flue curing illuminates the secrets behind the captivating flavors and aromas found in your favorite tobacco products.

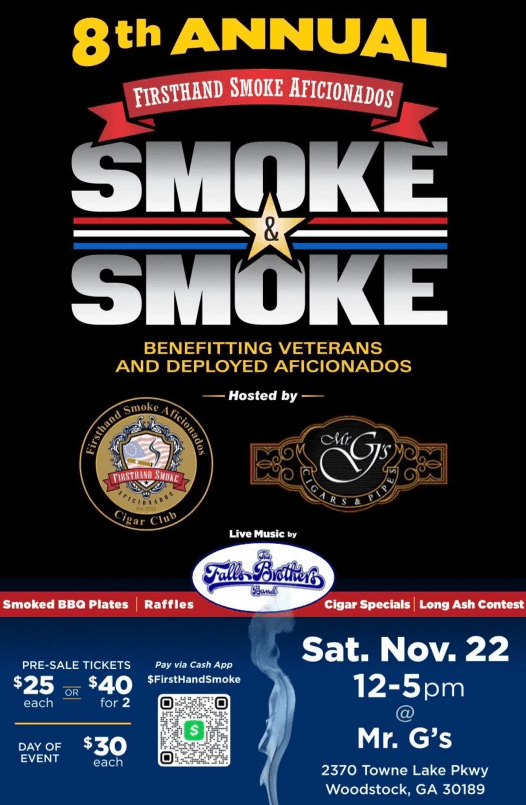

At Mr. G’s Cigar and Pipe Shop, we stock a wide range of a cigar brands and accessories for cigar aficionados of all kinds. Regardless of your personal brand or smoking preferences, we’re sure to have something for you.

Learn more about our cigar brands and accessories by contacting us through our website form or calling us at (678) 494-6619. For a more involved smoking experience, connect with fellow smoking aficionados in our Woodstock Tobacco Lounge. Feel free to stop by and see us soon!