Tobacco has a long and complex history that has captivated people from around the world for centuries. From its humble beginnings as a wild plant in the Americas to its global popularity as a preferred recreational substance, tobacco has undergone a fascinating journey of cultivation and processing.

In this blog post, we will delve into the intricate process of tobacco harvesting – from the moment those first tiny seeds are planted in the field to the creation of a finely crafted cigar.

So join us on this captivating journey into the world of tobacco harvesting. Let’s uncover the secrets of this ancient trade and gain a new appreciation for the meticulous work that lies behind every puff of smoke. Get ready to be immersed in a story of nature’s bounty, human ingenuity, and the allure of a plant that has left an indelible mark on our history and culture.

From Seed to Harvest: Unveiling the Art of Tobacco Harvesting

The Origins of Tobacco: From Wild Plant to Cultivated Crop

Tobacco, a widely used plant, has a rich and fascinating history that dates back thousands of years. Its origins can be traced to the wild plant known as Nicotiana rustica, which was first discovered in the Americas. Over time, humans recognized the potential of this plant and began cultivating it into a valuable crop.

The journey of tobacco from a wild plant to a cultivated crop is a testament to human ingenuity and our ability to harness the resources around us. Initially, tobacco was consumed for its medicinal properties by indigenous cultures in the Americas. They believed it had healing powers and used it in various rituals and ceremonies.

As European explorers arrived in the Americas, they encountered tobacco and witnessed its widespread use among the indigenous populations. Recognizing its potential as a trade commodity, they introduced tobacco to Europe, where it quickly gained popularity. The demand for tobacco grew rapidly, leading to the establishment of tobacco plantations in various parts of the world.

Tobacco harvesting has come a long way since its humble beginnings as a wild plant. Today, it is a highly regulated industry, with strict quality control measures in place to ensure the safety and consistency of tobacco products. From the fields where it is grown to the cigars we enjoy, the journey of tobacco from plant to product is a testament to both the resilience of the plant itself and the skill and dedication of those involved in its cultivation and processing.

From Seed to Seedling: The Delicate Process of Tobacco Germination

Tobacco harvesting is a complex and intricate process that involves several stages, from seed to seedling. This delicate journey begins with the germination of tobacco seeds, which marks the start of the tobacco cultivation process.

The first step in tobacco germination is the selection of high-quality seeds. Farmers carefully choose seeds from healthy and disease-free tobacco plants to ensure optimal growth and yield. These seeds are small and delicate, requiring careful handling to ensure their viability.

Once the seeds have been selected, they are sown in specially prepared seedbeds. The seedbeds provide the perfect environment for the seeds to germinate and develop into seedlings. They are carefully watered and monitored to ensure the ideal conditions of moisture and temperature are maintained.

Tobacco seeds are incredibly tiny, measuring only about 1mm in size. They are usually sown at a shallow depth, covered with a thin layer of soil or vermiculite. This ensures that the seeds receive sufficient light for germination while also protecting them from drying out.

Germination typically takes around 7 to 14 days, depending on the variety of tobacco being cultivated. During this period, the seeds absorb moisture, causing them to swell and split open. Tiny roots start to emerge, followed by delicate shoots that eventually develop into seedlings.

Once the seedlings have grown to a suitable size, they are carefully transplanted into the field. This is a crucial stage in the tobacco cultivation process, as it determines the overall health and productivity of the plants. Farmers must ensure that the seedlings are properly spaced and planted at the right depth to promote optimal growth.

Throughout the germination process, farmers need to provide constant care and attention to the seedlings. They must monitor the moisture levels, protect the delicate seedlings from pests and diseases, and provide appropriate nutrition to ensure their healthy development.

Transplanting and Nurturing: The Careful Cultivation of Tobacco Plants

Transplanting is a crucial step in the cultivation of tobacco plants. It involves carefully uprooting the seedlings from their nursery beds and transferring them to the designated fields. This process requires precision and care to ensure that the seedlings are not damaged during the transplantation.

Before transplanting, the fields need to be prepared adequately. The soil must be loosened and enriched with organic matter to provide a fertile environment for the tobacco plants to grow. The fields should also be free from weeds and other competing plants that might hinder the growth of the tobacco.

Once the fields are ready, the young tobacco seedlings are gently lifted from the nursery beds and placed into the prepared holes in the field. It is important to plant the seedlings at the right depth and spacing to allow for optimal growth. The seedlings should be spaced evenly to ensure that each plant has enough space to develop fully.

After transplanting, the tobacco plants require constant nurturing and care. They need regular watering, especially during dry periods, to ensure that they receive adequate moisture. Irrigation systems are often used to provide a consistent water supply to the plants.

The Challenges of Tobacco Farming: Weather Patterns and Pest Control

Tobacco farming is not without its challenges, particularly when it comes to weather patterns and pest control. These two factors can greatly impact the success and yield of the tobacco crop. Understanding and managing these challenges are crucial for tobacco farmers to ensure a profitable harvest.

Weather patterns play a significant role in tobacco farming. The growth and development of tobacco plants are highly dependent on factors such as temperature, rainfall, and sunlight. A sudden change in weather conditions can have detrimental effects on the crop. For instance, excessive rainfall can lead to waterlogged soil, which hampers root development and increases the risk of diseases. On the other hand, drought conditions can stunt the growth of tobacco plants and reduce leaf quality.

To mitigate the impact of weather patterns, tobacco farmers employ various techniques. They monitor weather forecasts closely and take preventive measures such as irrigation systems to ensure adequate water supply during dry spells. Additionally, farmers may use protective covers or shade structures to shield the crop from extreme temperatures or heavy rainfall. These measures help to maintain optimal growing conditions and protect the tobacco plants from weather-related damage.

Pest control is another significant challenge in tobacco farming. Various pests, including insects, nematodes, and fungi, pose a threat to the tobacco crop. Insects like aphids, tobacco budworms, and flea beetles feed on the leaves, causing significant damage. Nematodes infect the roots, leading to stunted growth and poor yield. Fungal diseases, such as black shank and blue mold, can devastate entire fields if left unchecked.

Tobacco farmers employ integrated pest management strategies to combat these pests effectively. This approach combines various pest control methods, including cultural practices, biological control, and judicious use of pesticides. Crop rotation, removal of crop residues, and proper sanitation help to reduce pest populations.

Beneficial insects and nematodes are introduced to prey on or parasitize harmful pests. When necessary, farmers may use targeted pesticides to control pest outbreaks while minimizing environmental impact.

Harvesting Techniques: Selecting the Perfect Time to Collect Tobacco Leaves

Tobacco harvesting is a meticulous process that requires careful consideration of several factors, one of the most important being the timing of leaf collection. Selecting the perfect time to harvest tobacco leaves is crucial in order to achieve the desired flavor and quality.

There are several indicators that growers use to determine when tobacco leaves are ready for harvest. One such indicator is the color change of the leaves. As the leaves mature, they transition from a bright green color to a pale yellow or brown. This color change signifies that the leaves have reached their peak in terms of nicotine content and flavor development.

Another method for determining the ideal time for tobacco leaf collection is by closely monitoring the physical appearance of the plants. Growers examine the condition of the leaves, looking for signs of ripeness such as their texture and thickness. Leaves that are too thin or brittle may not have developed the desired flavors and should be left on the plant for further maturation.

In addition to visual cues, growers also rely on tactile assessments to determine when the tobacco leaves are ready for harvest. They gently squeeze the leaves, feeling for a slight firmness and elasticity. If the leaves feel too soft or mushy, it indicates that they are not yet fully developed and should be left on the plant for a longer period. On the other hand, leaves that are too firm and unyielding may have passed their peak and could result in a harsh taste.

Environmental factors also play a significant role in determining the ideal time for tobacco harvesting. Growers consider the weather conditions, including temperature and humidity levels. These factors can influence the growth and maturation rate of the tobacco plants. For instance, warmer temperatures and higher humidity levels can accelerate the ripening process, while cooler temperatures may lead to slower leaf development.

Furthermore, the type of tobacco being harvested also impacts the timing of leaf collection. Different varieties have varying maturation periods, with some taking longer to reach their optimal flavor profile. Growers must be familiar with the specific characteristics of the tobacco they are cultivating to accurately determine the ideal harvesting time.

Curing and Fermentation: The Transformative Steps in Tobacco Processing

Tobacco harvesting is just the beginning of a fascinating journey that transforms the raw leaves into the flavorful cigars enjoyed by many. Two essential steps in this process are curing and fermentation. Let’s delve into these transformative stages and understand their significance in tobacco processing.

Curing, the first step after harvesting, aims to remove moisture from the tobacco leaves. This process is crucial as it stabilizes the flavors and aromas while enhancing the overall quality of the tobacco. There are two primary methods of curing: air curing and flue curing.

Air curing involves hanging the freshly harvested tobacco leaves in large barns or structures. The leaves are carefully arranged, allowing natural airflow to circulate. Over the course of several weeks, the leaves gradually lose moisture, turning from a vibrant green to a rich, golden brown. This method is commonly used for Burley and Dark Fired tobacco varieties.

On the other hand, flue curing employs heat to speed up the curing process. The harvested leaves are placed in chambers equipped with heaters that blow warm air over them. This method is particularly suitable for Virginia and Brightleaf tobacco types. The controlled heat accelerates the curing time, resulting in leaves with a brighter color and a sweeter taste.

Once the leaves have undergone the curing process, they move on to the next transformative stage: fermentation. Fermentation is a controlled aging process that further develops the flavors and aroma of the tobacco. Here, the cured leaves are piled together in large stacks called “bulks” or “pilons.”

During fermentation, heat is generated through the microbial breakdown of organic compounds within the leaves. This heat triggers chemical reactions that transform the tobacco’s characteristics. The bulks are carefully monitored, with the temperature and humidity levels precisely controlled. This process can last anywhere from a few months to a couple of years, depending on the desired outcome.

As the tobacco ferments, it undergoes significant changes. The harshness of the raw leaves diminishes, and the flavors become richer and more complex. The process also reduces the nicotine content, resulting in a smoother smoking experience. Fermentation is crucial in achieving the desired taste and aroma of the final tobacco product.

Once the fermentation is complete, the tobacco is ready for further processing, which includes sorting, grading, and aging. These steps ensure that only the highest quality leaves make their way into premium cigars, pipe tobacco, or other tobacco products.

Sorting and Grading: Classifying Tobacco Leaves for Quality Control

Sorting and grading play a crucial role in the quality control of tobacco leaves. This process ensures that only the best leaves are selected for further processing. The journey of tobacco leaves, from the field to the cigar, involves meticulous classification to maintain consistent quality.

When it comes to tobacco harvesting, the sorting and grading process begins after the leaves are carefully picked from the tobacco plants. These leaves undergo a series of assessments to determine their quality and suitability for different purposes.

Sorting involves separating the leaves based on their size, color, and texture. This step helps in identifying any damaged or inferior leaves that need to be discarded. Through careful observation and manual selection, the tobacco leaves are categorized into different grades, such as wrapper, binder, and filler.

Grading, on the other hand, involves further classifying the sorted leaves based on specific characteristics. This step helps in determining the flavor, aroma, and burning qualities of each leaf. Grading is typically done using a standardized system that assigns a grade or rating to each leaf based on its overall quality.

Various factors are taken into consideration during the sorting and grading process. These include leaf thickness, moisture content, vein structure, and overall appearance. Each factor contributes to the final quality and flavor profile of the tobacco leaves.

The importance of sorting and grading cannot be overstated in the tobacco industry. It ensures that only the finest leaves are used in the production of premium cigars, cigarettes, and other tobacco products. By carefully selecting and classifying the leaves, manufacturers can maintain consistency in flavor and overall smoking experience.

In addition to maintaining quality, sorting and grading also help tobacco farmers and traders to determine the value and marketability of their products. Higher-quality leaves command better prices, while inferior leaves may be sold for other purposes, such as pipe tobacco or cigar fillers.

Rolling and Aging: The Art of Crafting Fine Cigars

Rolling is the process of carefully wrapping the tobacco leaves to create the cigar’s structure. Highly skilled artisans, known as torcedores, perform this delicate task. They select the finest tobacco leaves and carefully arrange them in a way that ensures an even burn and optimal draw.

The quality of the tobacco leaves used in the rolling process is of utmost importance. Tobacco harvesting plays a vital role in obtaining the finest leaves. Harvesting tobacco is a fascinating journey that begins in the fields.

Tobacco harvesting involves a series of carefully timed steps. The leaves are picked by hand once they have reached the ideal level of maturity. Skilled farmers assess the color, texture, and aroma of the leaves to determine the perfect moment for harvesting. This attention to detail ensures that only the highest quality tobacco leaves are selected for cigar production.

Once the leaves are harvested, they undergo a curing process. This process involves carefully drying the leaves to remove excess moisture and develop the desired flavors. Proper curing is crucial as it contributes to the overall taste and character of the cigar.

After the leaves have been cured, they are ready for the rolling process. The torcedores skillfully arrange the leaves, ensuring that the filler, binder, and wrapper are perfectly aligned. The filler, made up of a blend of tobacco leaves, provides the core of the cigar and influences its strength and flavor. The binder, a single leaf, holds the filler together, while the wrapper, the outermost leaf, gives the cigar its appearance.

Once the cigars are rolled, they undergo the aging process. Aging is a crucial step that allows the flavors of the tobacco to develop and harmonize. During this period, the cigars are carefully stored in temperature and humidity-controlled environments. The aging process can range from several months to several years, depending on the desired flavor profile.

Aging not only enhances the taste and aroma of the cigars but also improves their combustion properties. It allows the flavors to mellow and blend, resulting in a smoother smoking experience. The patience and dedication required for proper aging are what contribute to the creation of fine cigars.

Conclusion: Reflecting on the Fascinating Journey of Tobacco Harvesting

Reflecting on the fascinating journey of tobacco harvesting, it is evident that every stage plays a vital role in producing the cigars we know and love. From the careful cultivation of seedlings to the meticulous curing and aging processes, each step is a testament to the dedication and craftsmanship of those involved.

As cigar enthusiasts light up their favorite smoke, they can appreciate the rich history and intricate journey that each tobacco leaf has undertaken. The fascinating world of tobacco harvesting truly adds depth and flavor to the pleasure of enjoying a well-crafted cigar.

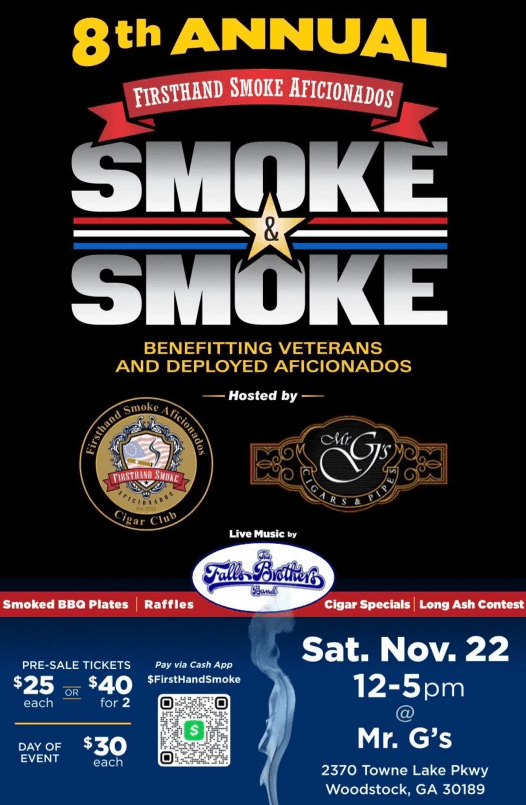

Enjoy the culmination of the work and care put into producing a single cigar with the wide selection available at Mr. G’s Cigar and Pipe Shop! With plenty of cigar brands and accessories to choose from, you are sure to find a cigar that meets your specific preferences.

Find the best cigar brands and accessories for you through our site’s contact form or by giving us a call at (678) 494-6619. If you want to go even deeper into the world of cigar smoking, check out our Woodstock Tobacco Lounge and elevate your cigar-smoking experience with fellow aficionados. Come and see us today!